ÜRKER CHILLER

UC ASH Series

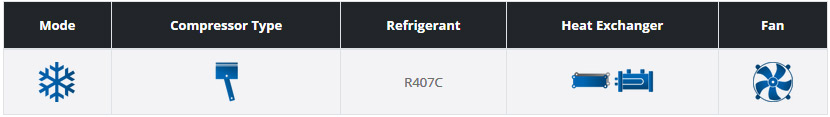

Air Cooled Chiller

Cooling Capacity 17 kW - 409 kW

SPECIFICATIONS

Ürker Chiller units have been designed to provide cold-water output temperatures on the capacity panel with the CE certificate located in our factory in where ISO 9001: 2008 Quality Management System is applied. Chiller units are delivered as ready-to-be installed in place with all sorts of pipe and cable connections done, gas-oil charges performed and with all the required conducted in our factory.

Cooling Compressor : 1 or 2 pieces semi-hermetic reciprocating compressors are used according to capacity. Ability to reach and apply maintenance to each part of compressor is provided. Required power supply is 3 ph - 400 Volt - 50 Hz.

Condenser : Air cooled condensers are manufactured by pipes and aluminum fins

Fan : The high efficient axial fan which is directly coupled with the motor is mounted on the device to provide the condensation of the refrigerant in the air cooled water chillers.

Evaporator : Direct expansion evaporator is manufactured in Shell & Tube form and special high efficient copper tubes are fixed to grooved steel tubesheet holes with tube expander method. It's allowed to maintenance and clean up because of the removable tube bundle. Evaporators are in conformity with EN 13445-3 and ASME Section VIII Div.1 standarts and designed for chilling water and glycol brines. External surface of evaporators and suction lines are insulated with insulation material with suitable thickness.

Components Of The Cooling Circuit : For the machine to operate automatically and securely; drier filter, sight glass, thermostatic expansion valve,solenoid valve, low-high pressure switch, water flow-switch, liquid shut-off valves, discharging valves for water and air are included.

Water Pump : Mounted so as to provide the water circulation between the chiller and the plant. The pump is chosen according to the pressure loss in the pipeline.

Water Tank : Inside the unit, there is a cylindrical cold water tank which have enough volume. Tank is isolated with suitable material against the heat losses and condensation.

Microprocessor Control System : Due to the microprocessor control system utilized in devices, water input and output temperatures, gas pressures at suction and force, superheat temperature originating in the evaporators, uptimes of the compressors, the entire breakdowns occurred and the entire breakdown records occurred in the past can be seen digitally on the screen and the capacity control can be performed with ease. Besides, uptimes of each of the compressors are balanced and therefore functioning of the device with optimum efficiency is ensured. As available upon request, a module can be attached which enables us to access and control vast range of data by creating a web-based connection with the help of a remote control. The control panel is located on the chiller unit and the entire connections are made in the factory.

Electrical Control Panel : The panel is designed to IP54. To operate the Unit automatically and securely, the panel is composed of two different section. The first section is power section and the other one is control section.The panel is equipped with enough number of contactors, thermics,fuses and on-off switchs. The panel and wiring are in conformity with EN 60204-1 standart.